Quality Control & Quality Assurance

ISO 9001:2015 Registered

Quality Management System

We strive to delight our customers with high-quality products, timely deliveries, and excellent service.

Advanced Cable Bus, Inc. employs an ISO 9001:2015 registered Quality Management System (assessed and certified by NSF-ISR). Our Quality Management System codifies the checkpoints and standards that ensure our ability to produce consistent, high-quality outputs at all stages of design and production. Our goals and standards will always be driven by our customers - we thrive on feedback, so drop us a line and let us know what you think!

System Design & Construction

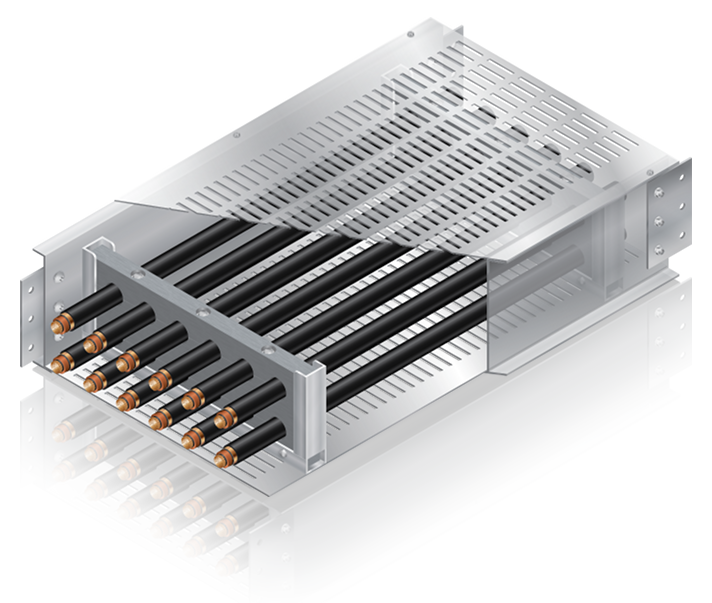

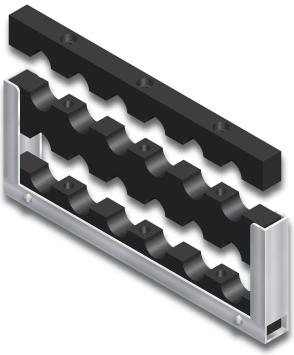

Typical Cable Bus Assembly

Sturdy, All-Weather, Easy to Install & Maintenance-Free

6063-T6 Aluminum Enclosures

Each Advanced Cable Bus system begins with a compact enclosure design. Once the initial goal of maintaining equal and constant spacing of the system's conductors is reached, the height and width of the enclosure can be customized to suit our clients' spatial requirements.

Spacing the conductors appropriately allows the power cables in our systems to operate with a free air rating at maximum ampacity. This reduces the total number of conductors per system, which in turn allows us to minimize the dimensions of the enclosure that houses them.

Every Advanced Cable Bus system is custom designed and manufactured per client specifications. Our standard, all-welded enclosures are made of structural grade 6063-T6 aluminum alloy, which is extremely sturdy and weather-resistant. All our welds are made inside the enclosure, lending a cleaner, more aesthetically pleasing look to the entire system.

↑Power cables are shipped on large, wooden reels for easy transport and installation.

Insulated Power Cables

Single conductor, insulated power cables form the core of every Advanced Cable Bus system. Our systems are designed to employ cable types that are approved for both indoor and outdoor use, ensuring a safe, reliable power supply, regardless of environmental conditions.

Great care is taken to select the proper cables for your project, and Advanced Cable Bus only furnishes cable from manufacturers with outstanding reputations for quality and service. Conductors are selected in reference to each client's specified system voltage class, insulation and jacketing materials, and desired flame test rating. The number of cables used in each system is determined based on the amperage, voltage drop and maximum operating temperature requirements.

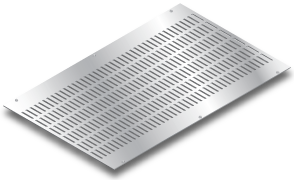

↑Both top and bottom covers of the Cable Bus enclosure are 50% ventilated to maximize the free air rating of the power cables inside.

Ventilated Enclosure Covers

The top and bottom covers of our enclosures are flat, slotted aluminum sheets with ¼" by 2" openings and 50% open area for maximum ventilation. The bottom covers are factory welded in place to the enclosure side rails, while the top covers are fastened to the housing with self-drilling screws and are easily removable for system inspection. Our Short Circuit Braces are factory welded to the side rails as well for additional mechanical strength and a more compact housing.

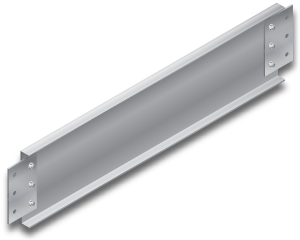

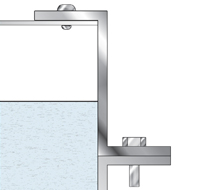

No.1-Form Enclosure Side Rails

Advanced Cable Bus system enclosures are manufactured using extruded, structural grade 6063-T6 aluminum side rails. Our uniquely-shaped side rails create a stronger enclosure, which allows for longer spans (up to 20 feet). These longer spans can drastically reduce the amount of support material required for your project.

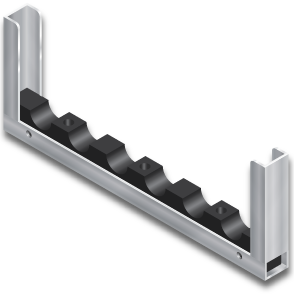

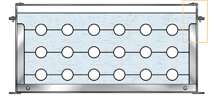

↑Short-circuit braces are welded to the inside the Cable Bus enclosure at regular intervals per NEC requirements. The bottom row of Cable Support Blocks are pre-installed as shown.

U-Form Short-Circuit Braces

Our industry exclusive, U-shaped Short Circuit Braces lend additional strength and rigidity to the Cable Bus enclosure. Constructed from 6063-T6 aluminum and factory welded to the enclosure side rails, the Short Circuit Braces serve a dual purpose. Though their primary functions are support and protection, they serve to streamline the Cable Bus installation process as well.

Short Circuit Braces hold the Cable Support Blocks in place, helping to maintain conductor spacing. Together with the Cable Support Blocks, they allow our systems to withstand short circuit mechanical forces of up to 100kA RMS.

Short Circuit Braces are also helpful during installation: they allow the power cables and Cable Support Blocks to be installed without the hassle of temporarily installing block clamping bolts until after all of the cables are in place. This is true for both horizontal and vertical bus runs.

Cable Support Blocks

Each system's power cables are firmly supported within the Cable Bus enclosure by our Cable Support Blocks. Our standard Cable Support Blocks are made from treated hard-rock maple wood which is primed and coated with fire retardant paint. High-density polyethylene (HDPE) Cable Support Blocks are also available.

Our Cable Support Blocks are high-strength, non-conductive, nontracking, non-hygroscopic, and will not degrade at high temperatures or in the presence of pollution or ultraviolet light. Our systems are designed to withstand a wide range of environmental conditions and are extremely reliable, boasting an average service life of over 40 years.

Cross-Sections & Dimensions

Typical Enclosure Dimensions

600 V Enclosure Dimensions by Ampacity

| Typical Ampacity |

Enclosure Height |

Nominal Width (Bottom Cover) |

Top Cover Width |

Number of Power Cables |

|---|---|---|---|---|

| 800A | 6" | 10" | 12" | 3 × 750 MCM |

| 1200A | 6" | 10" | 12" | 6 × 500 MCM |

| 1600A | 6" | 10" | 12" | 6 × 750 MCM |

| 2000A | 6" | 16" | 18" | 12 × 500 MCM |

| 2500A | 6" | 16" | 18" | 12 × 500 MCM |

| 3000A | 6" | 18" | 20" | 12 × 750 MCM |

| 3500A | 10" | 16" | 18" | 15 × 750 MCM |

| 4000A | 10" | 18" | 20" | 18 × 750 MCM |

| 4500A | 10" | 20" | 22" | 21 × 750 MCM |

| 5000A | 10" | 24" | 26" | 24 × 750 MCM |

| 6000A | 10" | 24" | 26" | 27 × 750 MCM |

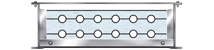

↑ 600V-800A System Cross-Section

↑ 600V-3000A System Cross-Section

↑ 600V-6000A System Cross-Section

5 kV Enclosure Dimensions by Ampacity

| Typical Ampacity |

Enclosure Height |

Nominal Width (Bottom Cover) |

Top Cover Width |

Number of Power Cables |

|---|---|---|---|---|

| 800A | 6" | 10" | 12" | 3 × 750 MCM |

| 1200A | 6" | 10" | 12" | 6 × 500 MCM |

| 1600A | 8" | 10" | 12" | 6 × 750 MCM |

| 2000A | 8" | 18" | 20" | 12 × 500 MCM |

| 2500A | 8" | 18" | 20" | 12 × 500 MCM |

| 3000A | 8" | 20" | 22" | 12 × 750 MCM |

| 3500A | 10" | 18" | 20" | 15 × 750 MCM |

| 4000A | 10" | 24" | 26" | 18 × 750 MCM |

| 4500A | 10" | 24" | 26" | 21 × 750 MCM |

| 5000A | 10" | 26" | 28" | 24 × 750 MCM |

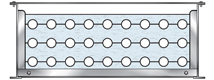

↑ 5kV-1600A System Cross-Section

↑ 5kV-3500A System Cross-Section

↑ 5kV-5000A System Cross-Section

15 kV Enclosure Dimensions by Ampacity

| Typical Ampacity |

Enclosure Height |

Nominal Width (Bottom Cover) |

Top Cover Width |

Number of Power Cables |

|---|---|---|---|---|

| 800A | 6" | 10" | 12" | 3 × 750 MCM |

| 1200A | 8" | 10" | 12" | 6 × 500 MCM |

| 1600A | 8" | 12" | 14" | 6 × 750 MCM |

| 2000A | 8" | 24" | 26" | 12 × 500 MCM |

| 2500A | 8" | 24" | 26" | 12 × 500 MCM |

| 3000A | 8" | 24" | 26" | 12 × 750 MCM |

| 3500A | 12" | 18" | 20" | 15 × 750 MCM |

| 4000A | 12" | 24" | 26" | 18 × 750 MCM |

| 4500A | 12" | 24" | 26" | 21 × 750 MCM |

| 5000A | 12" | 28" | 30" | 24 × 750 MCM |

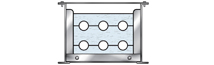

↑ 15kV-4000A System Cross-Section

↑ Z-Member on 12" Enclosures

35 kV Enclosure Dimensions by Ampacity

| Typical Ampacity |

Enclosure Height |

Nominal Width (Bottom Cover) |

Top Cover Width |

Number of Power Cables |

|---|---|---|---|---|

| 800A | 6" | 12" | 14" | 3 × 500 MCM |

| 1200A | 8" | 12" | 14" | 6 × 500 MCM |

| 1600A | 8" | 18" | 20" | 9 × 500 MCM |

| 2000A | 8" | 18" | 20" | 9 × 500 MCM |

| 2500A | 8" | 24" | 26" | 12 × 500 MCM |

| 3000A | 12" | 18" | 20" | 15 × 500 MCM |

| 3500A | 12" | 24" | 26" | 18 × 500 MCM |

↑ 35kV-2000A System Cross-Section

NOTEThere are 9 power cables in our 35kV-1600A and 35kV-2000A systems, as shown above. The additional (10th) bore in the Cable Support Blocks for these systems is intentionally left empty.

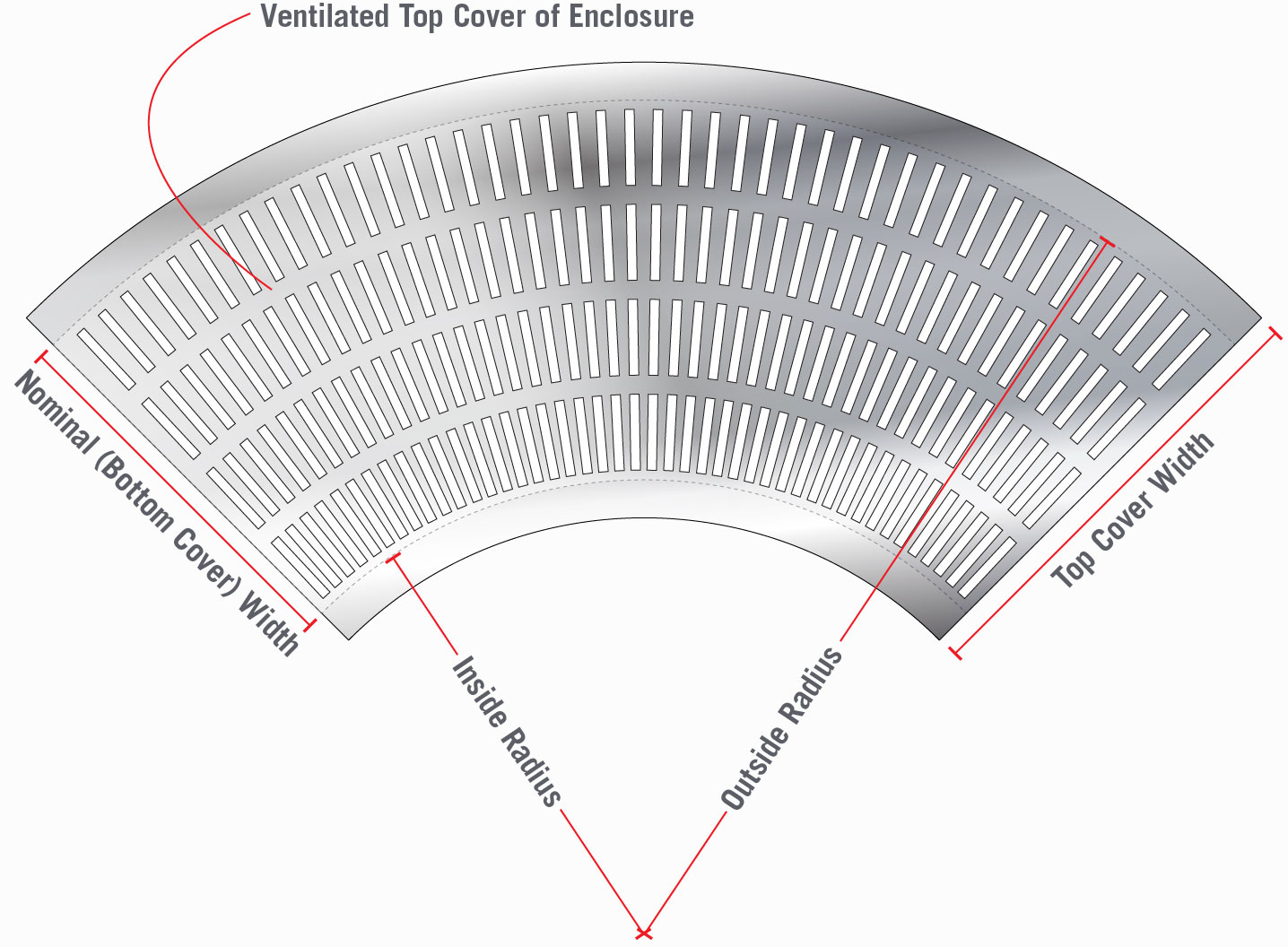

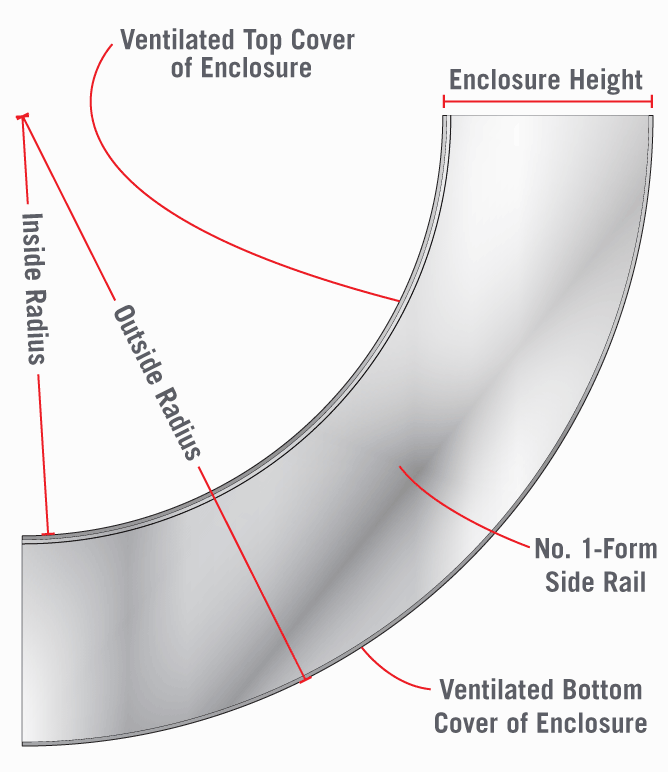

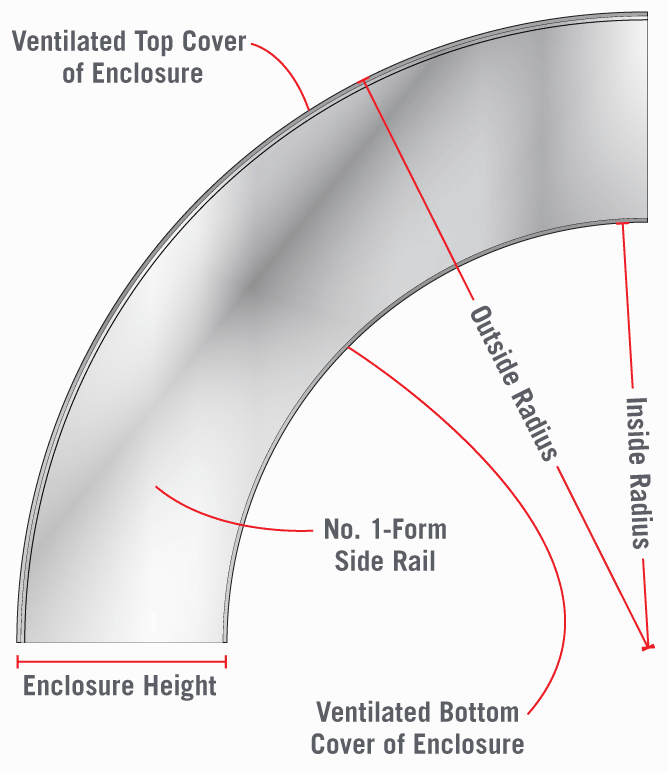

Typical Elbow Dimensions

Our horizontal and vertical elbows are curved to follow the radius of the power cables perfectly. Standard elbows can have an inside radius of 12", 18", 24" or 36". The inside radius of the elbows is determined according to the minimum bending radius of the selected power cables and design space requirements. Standard horizontal and vertical elbows come in 15°, 30°, 45°, 60° and 90° bends. Custom elbows are also available to meet your specific job requirements.

Typical 90° Horizontal Elbow

(↓ Plan View)

Typical Horizontal Elbow Dimensions

| Nominal Width |

Top Cover Width |

Inside Radius |

Outside Radius |

|---|---|---|---|

| 10" | 12" | 12" | 22" |

| 10" | 12" | 18" | 28" |

| 10" | 12" | 24" | 34" |

| 10" | 12" | 36" | 46" |

| 12" | 14" | 12" | 24" |

| 12" | 14" | 18" | 30" |

| 12" | 14" | 24" | 36" |

| 12" | 14" | 36" | 48" |

| 16" | 18" | 12" | 28" |

| 16" | 18" | 18" | 34" |

| 16" | 18" | 24" | 40" |

| 16" | 18" | 36" | 52" |

| 18" | 20" | 12" | 30" |

| 18" | 20" | 18" | 36" |

| 18" | 20" | 24" | 42" |

| 18" | 20" | 36" | 54" |

| 20" | 22" | 12" | 32" |

| 20" | 22" | 18" | 38" |

| 20" | 22" | 24" | 44" |

| 20" | 22" | 36" | 56" |

| 24" | 26" | 12" | 36" |

| 24" | 26" | 18" | 42" |

| 24" | 26" | 24" | 48" |

| 24" | 26" | 36" | 60" |

Typical Vertical Elbow Dimensions

| Enclosure Height |

Inside Radius |

Outside Radius |

|---|---|---|

| 6" | 12" | 18" |

| 6" | 18" | 24" |

| 6" | 24" | 30" |

| 6" | 36" | 42" |

| 8" | 12" | 20" |

| 8" | 18" | 26" |

| 8" | 24" | 32" |

| 8" | 36" | 44" |

| 10" | 12" | 22" |

| 10" | 18" | 28" |

| 10" | 24" | 34" |

| 10" | 36" | 46" |

| 12" | 12" | 24" |

| 12" | 18" | 30" |

| 12" | 24" | 36" |

| 12" | 36" | 48" |

↑90° Vertical Outside Elbow (with Cable Support Blocks)

Typical 90° Vertical Inside Elbow |

Typical 90° Vertical Outside Elbow |

|

|

(↑ Elevation View) |

(↑ Elevation View) |

Accessories & Customization

Every project is unique...

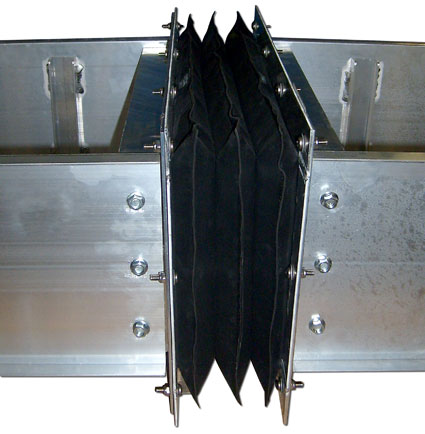

We will provide the necessary equipment to ensure your project is successful, on-time and, in most cases, under budget. In addition to all of the accessories listed below, we can provide flash barriers (for Arc Resistant Switchgear), flexible joints (when vibration is an issue) and copper bus bars. We are here to provide the engineering, expertise and equipment to see that your project is a success.

Our default enclosure material is high-strength, 6063-T6, structural grade aluminum alloy. The No. 1 Form Side Rails are extruded, and the Top and Bottom Covers are flat, ventilated sheets. Aluminum enclosures can be powder-coated or anodized. Stainless steel, and hot-dipped, galvanized (after fabrication) steel are also available.

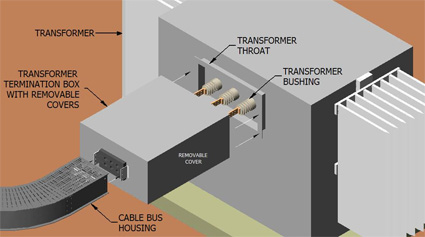

Termination Boxes

We can design and build boxes to meet the system requirements. Tap Boxes, transformer Termination Boxes and switchgear/MCC top hats are all available to provide the necessary space to complete the installation. The boxes are constructed from aluminum angle frames, seam welded for outdoor applications, stitch welded for indoor applications, and have removable panels for easy access.

Advanced Cable Bus Termination Boxes ensure sufficient space is available to terminate conductors to electrical equipment. Outdoor boxes use gasketed removable panels, fully seam welded fixed panels, and an HDPE equipment seal block to ensure a water-tight enclosure.

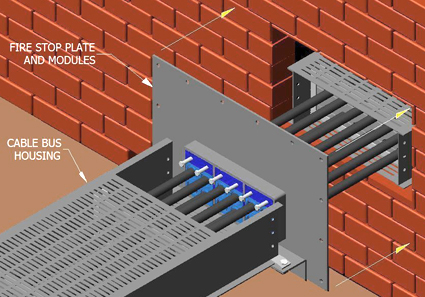

MCT Firestops

We use MCT (Multi Cable Transit) type Fire Stops to provide a 2-hour rated, UL listed fire barrier. MCT seals are used when an absolutely watertight fitting is required. All installation hardware included.

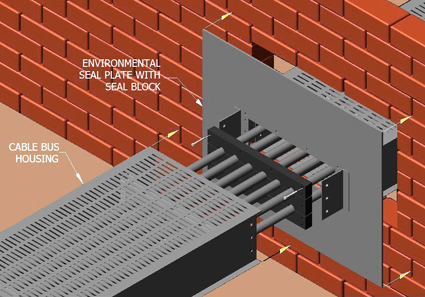

Environmental Seals

Our Environmental Seals form a watertight seal with walls when a fire barrier is not required. They can also be used for floor penetrations that must be watertight. Conductors are sealed with Silicone sealant. Entrance fittings are furnished with all included hardware. Neoprene or high-density polyethylene (HDPE) blocks are inserted after the cables are installed for ease of pulling.

Equipment Applications

Please contact the factory for more information.

Wall Applications

Please contact the factory for more information.

Floor Applications

Please contact the factory for more information.

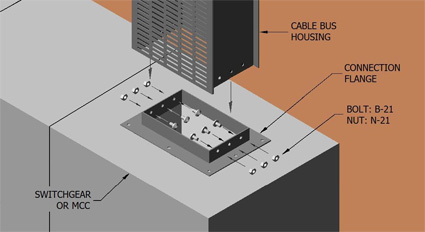

Connection/Bus End Flanges

Connection Flanges are used to connect the Cable Bus housing to the indoor electrical equipment (switchgear, motor control center, etc.)

Cable Accessories

↑A NEMA standard Two-Hole Long Barrel compression lug.

Termination Lugs

NEMA standard Two- and Four-Hole Long Barrel compression lugs are used to terminate the power cables to the bus bars inside of electrical equipment. Each termination comes complete with Silicon Bronze termination hardware to attach the lugs to the termination points and ensure a reliable connection.

Termination Kits

Termination Kits are available in both heat shrink and cold shrink types and can be used either indoors or outdoors.

Special Accessories

Tap Boxes

Tap Boxes allow for intermediate load tapping. The design provides system voltage rated air separation between live parts and adjacent surfaces to eliminate the necessity of tapping all energized components. Typical Tap Boxes consist of an aluminum-framed enclosure, removable covers (gasketed for outdoor applications), porcelain or epoxy post stand-off insulators, and bus bars.

Flexible Connectors

Please contact the factory for more information.

Adapter Bus Bars

Please contact the factory for more information.

Standard System Specifications

General Cable Bus Specifications

- A complete, metal-enclosed Cable Bus system will be provided, including enclosure sections, insulated conductors, and all necessary accessories. Accessories may include, but are not limited to: fittings, equipment seals, wall/floor seals, fire stops, termination boxes, tap boxes, connection (bus end) flanges, termination lugs, termination kits, grounding accessories, and installation hardware.

The Cable Bus system, and all of its components, will be suitable for indoor and outdoor use. Adequate ventilation, and a minimum distance of one (1) cable diameter between conductors, will be maintained throughout the system. - All elements of the Cable Bus enclosure will be fabricated so as to eliminate any sharp edges that might damage conductor insulation or injure personnel.

- The Cable Bus system will be designed and manufactured in the United States of America by Advanced Cable Bus, Inc.

Construction Specifications

- The Cable Bus enclosure will be aluminum*, of welded construction and ventilated design, with No. 1 Form Side Rails manufactured from extruded, 6063-T6 aluminum alloy. The maximum allowed stress to be used in design is 10,000 PSI.

- Top and bottom covers of the Cable Bus enclosure will be slotted for ventilation. Ventilation openings will comprise 50% of the covers’ surface area, and openings will be sized to prevent a quarter-inch (¼") rod from penetrating the Cable Bus enclosure. Top covers will be fastened to the Cable Bus enclosure with No. 10 self-drilling screws, spaced 24 inches (on centers), allowing the covers to be easily removed for system inspection. Bottom covers will be factory installed and welded to the adjacent Side Rails to form an integral part of the Cable Bus enclosure.

- Each system’s elbows (offsets) will be designed to accommodate the cable type selected for that system. In no instance will the inside radius of an elbow be less than the minimum bending radius of the cable it will house.

- The splice joints that span adjoining sections of the Cable Bus enclosure will be reinforced with high-pressure bolts to ensure that structural integrity is maintained.

- Cable Support Blocks will be designed in segments, and will maintain a minimum distance of one (1) cable diameter between conductors in both vertical and horizontal planes. This spacing will allow the Cable Bus system to obtain a Free Air rating.

The Cable Bus enclosure will be designed with Cable Support Blocks throughout, spaced 36 inches (on centers) in horizontal straight sections, and 18 inches (on centers) in vertical straight sections and elbows. The Cable Support Blocks will prevent the power cables from moving and/or incurring damage during short circuit conditions. Cable Bus systems will be rated to withstand short circuit forces of 100kA (100,000 amperes) RMS symmetrical.

Electrical Specifications

- The Side Rails of the Cable Bus enclosure will be capable of carrying a continuous current rating of 1kA (1,000 amperes) without exceeding a 40°C temperature rise above ambient. Resistance across Cable Bus enclosure splice joints will not exceed 50 microhms. The Cable Bus enclosure will be grounded at sufficient intervals to prevent potential above ground from occurring in the event of a fault.

- Current conductors will be single conductor cables, insulated for an operating temperature of 90°C (in wet or dry locations) in accordance with ICEA P-46-426 interim STD #1 & 2 of ICEA publication #S-66-524, based on the specified system voltage and amperage.

- Conductors within the Cable Bus enclosure will have a specific phasing arrangement designed to minimize current imbalance between conductors, maintain a low-impedance power system, and minimize inter-phase and intra-phase imbalance.

- Interleaving of conductors within the Cable Bus enclosure will not be permitted. All current-carrying conductors are to be continuous (without any intermediate splices), and are to be pulled into place after the Cable Bus enclosure has been installed. Electrical connections will be made at equipment and/or tap points only. All cable termination materials will be furnished by Advanced Cable Bus, Inc.

- Current balance and temperature rise calculations will be made available upon request, in support of Advanced Cable Bus, Inc. Electrical Specifications #2 & 3 (above).

Engineering Calculations & Tests

The enclosure of a Cable Bus system is designed to withstand up to

100 kA symmetrical short-circuit current.

The cable configuration is designed to balance the current in each individual conductor and allow the cables to operate at their higest efficiency, where losses and imbalances between individual conductors are minimized.

To ensure an efficient, dependable, high-quality installation, every Advanced Cable Bus system is fully engineered with particular emphasis placed on power cables, phasing arrangement and system balance, short circuit capacity, and grounding requirements. Each one of these key design considerations must be analyzed separately to determine how it affects the design of the overall electrical power system.

Short-Circuit Capacity

A Cable Bus system must be able to withstand the mechanical forces created by short circuit currents. These forces are transferred from the conductors to the cable supports. The support elements in an Advanced Cable Bus system include the Cable Support Blocks, Short Circuit Braces and enclosure.

Short circuit currents are made up of two parts: a symmetrical AC component and a rapidly decreasing DC component. Cable Bus systems are designed to have the mechanical strength to withstand the maximum instantaneous current and the symmetrical current which may last several cycles. The symmetrical current is the actual value that the circuit breaker will interrupt.

Since Cable Bus systems are often used for main feeder connections (e.g. substation or generator to switchgear, load centers and high voltage machines), the available short circuit current will be that of the utility or generator supply through the transformers. In some cases, the Cable Bus system feeds large motors, and the motor contribution to potential short circuit forces must also be considered. Numerous tables are available listing motor contributions for various operating conditions.

Short-Circuit Tests & Data

↑A short-circuit test being run on an Advanced Cable Bus system.

The tests performed on a prototype 15kV 4000A Cable Bus were conducted similar to the tests outlined in IEEE C37.23. The tests were conducted on a 3 phase, 60 Hz circuit. One end of the Cable Bus was connected to the source terminals, and the other was short circuited to create a three phase bolted fault.

Advanced Cable Bus, Inc. systems have been subjected to currents of 100,000 RMS symmetrical amperes with instantaneous peaks greater than 200,000 amperes. The Cable Bus system withstood the mechanical forces of the test without any damage to the cables, support blocks or enclosure.

We are also able to supply type test reports, which demonstrate the short-circuit withstand capabilities and temperature rise data of a prototypical Cable Bus system.

Cable Bus System Calculations

Inductive Reactance calculations are available for every project. Based on the Carson’s Line method of calculation and written using MATLAB codes and actual cable data, the Inductive Reactance Program outputs include the amount of current distributed through each cable, voltage drops, power losses, three-phase impedance and symmetrical component impedances.

Please contact the factory for more information.

Temperature Rise Tests & Data

↑A temperature rise test being run on an Advanced Cable Bus system.

Advanced Cable Bus can provide heat-rise calculations, based on the client's installation configuration, showing the temperature rise of the conductors.

Please contact the factory for more information.

System Balance &

Parallel Conductors

The spacing of the conductors in a Cable Bus system is one cable diameter, (i.e. one to three inches). The objective of the Cable Bus design is to obtain the optimum balance for an electrical circuit using parallel conductors with no transposition and minimal imbalance. Advanced Cable Bus is designed for balance of conductors within a phase (intra-phase) and balance between the phases (interphase). Many phasing arrangements will provide inter-phase balance of currents due to the load impedance, but the majority of these phasing arrangements do not provide intra-phase current imbalance. The Advanced Cable Bus design provides a phasing arrangement that achieves interphase current balance, as well as intra-phase current balance, therefore reducing the amount of parallel conductor imbalance to a minimum. This helps prevent hot spots in the electrical circuits that can be caused by cables in the same phase being unbalanced.

Parallel conductors (more than one per phase) can be used to an advantage in Cable Bus where large conductor sizes are encountered. The ampacity per circular mil of conductor decreases as the circular mil of conductor increases. Smaller conductors running parallel are more flexible during installation and have greater current carrying capability than fewer, larger conductors.

Grounding Solutions

↑An installed Advanced Cable Bus system featuring an external grounding cable and firestop/wall seal.

An Advanced Cable Bus system must protect both life and property against faults caused by electrical disturbances. Lightning, electrical system failures, and failures in the system's corrective equipment all constitute possible fault hazard locations. For this reason, all metal enclosures of the system, as well as non-current carrying or neutral conductors should be tied together and reduced to a common potential. This includes the structural steel of the building, water, steam and gas piping.

All Advanced Cable Bus systems should be grounded to the substation or building ground grid through the Cable Bus support materials. Cable Bus should also be grounded to the equipment or switchgear enclosure by means of the connection accessory.

It is an accepted fact that ground currents tend to concentrate near power conductors and that cable enclosures take a large portion of the ground currents; therefore, it is important to consider Cable Bus as a major carrier of ground currents. The cable bus enclosure is designed to be able to carry large ground currents and is grounded in accordance with NEC 250.

Qualifications & Standards

Design Standards & Qualifications

Cable Bus is defined by the National Electric Code article 370 for use in the US, and the design and testing of Cable Bus systems by Advanced Cable Bus, Inc. is based on the IEEE C37.23 standard which covers the testing for bus ways, switchgear and controlgear for short circuit and temperature rise.

Cable Bus subcomponents are also designed and manufactured in accordance with their respective standards.

The table below lists the design standards for Cable Bus systems and components.

| System or Component | Qualification(s) & Standard(s) |

|---|---|

| Cable Bus System —Design & Ampacity |

NEC 370 NEC Table 310.15(B)(17) CSA CEC Tables 1 and 5A IPCEA P-46-426, IEEE 835 NEMA VE-1, NEMA VE-2 |

| Cable Bus System —Short Circuit & Temperature Rise |

IEEE C37.23 CSA CEC Part 1, C22.2 No. 27-10 (see below) |

| Power Cables

Actual specifications vary on a project-by-project basis. List to the right is partial and includes medium voltage and low voltage cables. |

ASTM B-3, ASTM B-496 ICEA S-95-658, ICEA S-93-639, ICEA S-97-682 AEIC CS8 NEMA WC-70, NEMA WC-74 UL 44, UL 854, UL 1581, UL 1072 IEEE 383, IEEE 1202 CSA FT1 and FT4, CSA C68.3 |

| Fire-Rated Wall Penetrations | Qualification and test reports available from: UL CSA American Bureau of Shipping (ABS) Det Norske Veritas (DNV) Lloyd’s Register of Shipping US Navy |

| Cable Termination Lugs | UL 468A-468B CSA Listed & Approved |

| System Grounding | NEC 250 |

| Medium Voltage Cable Termination | IEEE 48 |

Advanced Cable Bus, Inc. is also able to make design modifications within the standard parameters in order to meet client specifications or tailor the systems to match special requirements. Please note also that cable bus systems are available for sale in locations where IEC standards are required as well. Although there is no IEC standards that directly cover cable bus systems, in those cases the components will be selected based on qualifications for IEC standards.

UL Classified

Underwriters Laboratories, USA

Underwriters Laboratory (UL) does not have a classification file specifically for cable bus systems. However, there are UL classifications for all of the component parts including power cables, cable terminations, fire-stops, and cable bus enclosure parts.

Cable Bus enclosure side-rails are tested and classified by UL as grounding path in accordance with NEMA VE1 and NEC 392.60.

CSA Approval

Canadian Standards Association, Canada

In 2019, CSA has published the 2019 version of CSA C22.2 No. 273-14 (R2019) standard for cable bus, and the Canadian Electrical Code includes rules for cable bus installation and application (12-2250 through 12-2260). Since 2010, CSA has formed a committee to review and revise the standard for cable bus, and the committee membership has several cable bus manufacturers including Advanced Cable Bus, Inc.

Advanced Cable Bus, Inc. is in the process of obtaining certification for CSA C22.2 No. 273-14 (R2019). While the certification remains in process, each cable bus installation in Canada will require a special inspection by CSA or another approved certifying body such as Intertek, FM, or QPS. The inspection work is scheduled by Advanced Cable Bus, Inc. upon completion of installation at no additional cost to our customers.