Contact Us

Main Office

Phone |

1 (864) 990-5499 | |

Toll-Free |

1 (866) 578-8527 | |

Fax |

1 (864) 569-0766 | |

Address |

Advanced Cable Bus, Inc. P.O. BOX 14128 Greenville, SC 29610 |

|

Location |

3514 Old Buncombe Rd. Greenville, SC 29617 |

|

| sales@advcablebus.com | ||

Catalog |

Download our Catalog (5.5 MB) |

|

Department Heads |

||

Engineering |

Procurement |

Design |

Velko Lukovic |

Joshua R. Cable |

Andre Lukovic |

About Our Company

Our History & Mission

Advanced Cable Bus, Inc. was founded in 2007 by an experienced, technically savvy and team-oriented group of engineering professionals with more than 50 years combined experience in the power distribution industry.

Our team has grown since then, but our goals remain the same: produce safe, reliable, maintenance-free power systems; make them easy to install; and provide excellent service throughout every stage of every project.

Personalized customer service underlies our approach, guiding each project to completion and ensuring the best possible outcome for our clients and their businesses.

We look forward to working with you.

Cable Bus Overview

What is Cable Bus?

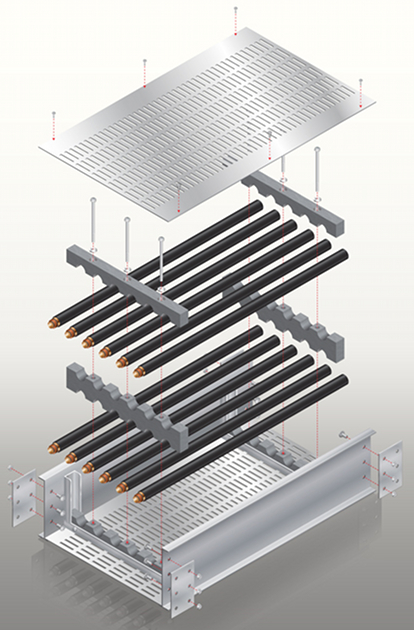

Cable Bus is a system for distributing power from one electrical apparatus to another using insulated power cables inside of a protective metal housing.

“An assembly of units or sections with insulated conductors having associated fittings forming a structural system used to securely fasten or support conductors and conductor terminations in a completely enclosed, ventilated, protective metal housing. This assembly is designed to carry fault current and to withstand the magnetic forces of such current.

Informational Note: Cablebus is ordinarily assembled at the point of installation from the components furnished or specified by the manufacturer in accordance with instructions for the specific job.”

—NEC 2014 (USA)

Section 370: Cablebus

Cable Bus is designed to carry large amounts of electrical power for use within power generation and industrial plants for service entrances, main feeders, distribution applications, and retrofits for existing power systems. Each Advanced Cable Bus system is custom designed and manufactured to meet your specific job requirements.

Uniform conductor spacing is maintained by our custom-manufactured Cable Support Blocks, which are themselves held in place by the U-Form Short Circuit Braces welded into each enclosure section. The combination of the Cable Support Blocks and the Short Circuit Braces allows our systems to withstand short circuit forces of up to 100kA RMS symmetrical, keeping personnel and equipment safe if a fault occurs.

Advanced Cable Bus manufactures enclosure covers that are 50% ventilated. The ventilation and conductor spacing allow our systems to operate at free air rating. Each cable can conduct more power without a corresponding rise in temperature. Accordingly, Cable Bus systems employ fewer cables than cables in tray or cables in conduit, which impacts project costs significantly.

Advanced Cable Bus systems have an ampacity range from 800A to 6000A, and voltage ratings of 480V, 600V, 5kV, 15kV, 25kV, 35kV, and occasionally up to 69kV. Typical applications include connections between transformers and switchgear, tie connections between two pieces of switchgear, between motor control centers and large motors, or between generators and generator breakers or generator step-up transformers. We commonly work on industrial facilities and other types of applications where a large amount of current is needed.

Outside Sales

Sales Representatives

United States of America(Listed Alphabetically by State) | ||

Ala. – Md. |

Mass. – N.D. |

Ohio – Wyo. |

|

Colorado Applied Power Industrial Sales 11919 I-70 Frontage Rd. N. #103 Bob Krueger Connecticut PESCO Tel: 1 (978) 774-6680 Peter Asselin Illinois — Northern IL — T&D Products Tel: 1 (630) 791-9260 4200 Cantera Dr., Suite 216 sales@tdproducts.com — Southern IL —ADV Cable Bus Direct Dominique Lukovic Indiana — Northwestern IN — T&D Products Tel: 1 (630) 791-9260 sales@tdproducts.com — Rest of IN —ADV Cable Bus Direct Dominique Lukovic Maine PESCO Tel: 1 (978) 774-6680 Fred Derr |

Massachusetts

PESCO Tel: 1 (978) 774-6680 873 Turnpike St., Unit 104 R. Manual Breest

Michigan

— Upper Peninsula — T&D Products Tel: 1 (630) 791-9260 sales@tdproducts.com — Rest of MI —ADV Cable Bus Direct Dominique Lukovic Montana — Eastern MT — Applied Power Industrial Sales 11919 I-70 Frontage Rd. N. #103 Bob Krueger ADV Cable Bus Direct Dominique Lukovic New Hampshire PESCO Tel: 1 (978) 774-6680 Fred Derr New York — Upstate NY — PESCO Tel: 1 (978) 774-6680 Peter Asselin ADV Cable Bus Direct Dominique Lukovic |

Ohio

R.C. Childs Company Tel: 1 (440) 835-3500 26933 Westwood Rd., Ste 300 Rudy Najda

Rhode Island

PESCO Tel: 1 (978) 774-6680 Peter Asselin South Carolina Electrical Product Sales Billy Simon Vermont PESCO Tel: 1 (978) 774-6680 Fred Derr Wisconsin — Southeastern WI — T&D Products Tel: 1 (262) 781-9180 rwertschnig@tdproducts.com 4685 Old Church Rd. ADV Cable Bus Direct Dominique Lukovic Wyoming — Eastern WY — Applied Power Industrial Sales 11919 I-70 Frontage Rd. N. #103 Bob Krueger ADV Cable Bus Direct Dominique Lukovic |

Canada(Listed Alphabetically by Province) | ||

Alta. – Man. |

N.B. – P.E.I. |

Que. – Yuk. |

|

Alberta

T&D Products Tel: 1 (780) 419-7145 3-11 Bellerose Dr., Suite 204 Cyril Rundell British Columbia T&D Products Tel: 1 (780) 419-7145 3-11 Bellerose Dr., Suite 204 Cyril Rundell Manitoba Meg-a-Ron Engineering Tel: 1 (204) 338-0269 22 Mitchell Bay Rob Kost |

Northwest Territories T&D Products Tel: 1 (780) 419-7145 3-11 Bellerose Dr., Suite 204 Cyril Rundell |

Québec

Agence AMR Martin Roy 1502 rue du Volt ElectraSpec, Inc. Kenneth Russell-Murray 807 Ch Ste Anne des Lacs Saskatchewan T&D Products Tel: 1 (780) 419-7145 3-11 Bellerose Dr., Suite 204 Cyril Rundell Yukon T&D Products Tel: 1 (780) 419-7145 3-11 Bellerose Dr., Suite 204 Cyril Rundell |

International(Outside U.S.A. & Canada) | ||

|

Central & South America ADV Cable Bus Direct Dominique Lukovic |

Middle East & Africa ADV Cable Bus Direct Dominique Lukovic |

South Korea

Yoomin Enterprise Co. Tel: +82 (2) 589-1788 Seoul, South Korea I. S. Park |

Clients & Partners

ADV Clients & Partners

(Partial List)

ADV Installed Systems

Past Jobs & Current Projects

(Partial List)

Manitoba Museum of Human Rights

| Installation Type | Public Building Main Power Feeder |

| Client | Meg-A-Ron Engineering |

| Size | Medium, 3 Bus Runs |

| System Rating(s) | 600V Main Incoming, 1600A & 2500A |

| Description | The main power feeders for the new Museum of Human Rights in Winnipeg, Manitoba is comprised of multiple bus runs from transformer secondaries across a service road. The cable bus runs cross the service road via underground prefabricated trenches. The Museum design and construction, starting in 2009, is one of the most innovative in Canada and required flexibility for its electrical feeders as well as reliability and low cost, which led to cable bus as the choice for main feeders. |

Telecommunication Data Centers

| Installation Type | Data Center Main Feeders, Back-Up Feeders, and UPS Feeders |

| Clients | Multiple Electrical Contractors |

| Size | Multiple Projects, totaling over $1 million |

| System Rating(s) | 600V Service Feeders, 3000A – 5000A |

| Description | Power feeders for data centers normally include primary and back-up feeders for the supply circuits and UPS systems. In some locations, cable bus is used as back-up while other locations use cable bus for primary feeders as well. Companies that have used cable bus in their facilities in some capacity include AT&T, T-Mobile, Google, and Microsoft. Advanced Cable Bus, Inc. have supplied cable bus for various data centers in the South Eastern US. |

Oil Sands Facilities

| Installation Type | Oil Sands Extraction and Processing main medium voltage feeds, medium voltage and low voltage distribution load feeders |

| Clients | Multiple engineering firms and end users throughout Canada and US |

| Size | Multiple Projects, totaling over $1 million |

| System Rating(s) | 35kV, 15kV, 8kV, 5kV and 600V Service Feeders, 1200A – 4000A |

| Description | Several oil sands companies have specified cable bus as the preferred electrical feeder method over other methods, based on the design features, costs, and the ability to withstand extreme climate conditions outdoors without requiring constant maintenance. Companies that have used cable bus at their facilities include Shell Canada, Canadian Natural Resources Limited, Suncor, Husky Oil, and Petro Canada. |

Hydroelectric and Thermal Main Power Plant Feeders

| Installation Type | Main generator feeders for hydroelectric and thermal plants. |

| Clients | Multiple engineering firms and end users throughout Canada and US |

| Size | Multiple Projects, totaling over $ 1 million |

| System Rating(s) | 35kV and 15kV Feeders, 2500A – 4000A |

| Description | Power plants that require long feeder circuits or flexibility in routing have used cable bus as the feeder of choice. Thermal plants throughout North America have used cable bus, as well as hydroelectric plants in locations such as South America, Southeast Asia, and North America. |

Photoelectric Power Plant Collector Feeders

| Installation Type | Connection links from the photovoltaic solar arrays to the step-up transformers. |

| Clients | Multiple engineering firms throughout US |

| Size | Multiple Projects, totaling over $ 250,000 |

| System Rating(s) | 2kV and 600V |

| Description | Photovoltaic plants often consist of multiple arrays of PV panels that are collected and fed to step-up transformers before being connected to the main outgoing feeders. Cable bus has been used for the link between the collector switchgear and the step-up transformers in several PV plant installations throughout the Western US. The feeders are usually short in length, and the selection of cable bus for the feeder link is based on short-circuit withstand qualities and cost. |

Public Utility Substation Feeders

EATON Corporation| Client | |

| Location | New England, USA |

| System Rating(s) | 15kV-4000A and 5kV-2000A |

| Description | Provided two main feeders from a power company-owned power management building to step-up transformers. |

Frozen Food Plant Expansion Project

| Client | Nestlé USA |

| Location | South Carolina, USA |

| System Rating(s) | 5kV-2000A |

| Description | Provided a main feeder from a power company-owned transformer to the expanded electrical room for one of Nestlé's facilities. |

Pollard Banknote and Rice Lake Gold Projects

| Client | Meg-A-Ron Engineering |

| Location | Winnipeg, Manitoba, Canada |

| System Rating(s) | 600V-3000A and 1kV-2100A |

| Description | The Pollard Project is a main electrical feeder for an industrial facility. The Rice Lake Gold Project included machinery feeders for a mining operation. |

Healthcare Data Centers

| Installation Type | Data Center Main Feeders, Back-Up Feeders, and UPS Feeders. |

| Clients | Parsons Electric (Minneapolis, MN) |

| Size | Multiple Projects, totaling over $1 million |

| System Rating(s) | 600V Service Feeders, 3000A – 5000A |

| Description | Power feeders for data centers normally include primary and back-up feeders for the supply circuits and UPS systems. In some locations, cable bus is used as back-up while other locations use cable bus for primary feeders as well. For especially long circuit lengths in new constructions Advanced Cable Bus, Inc. performed calculations to ensure that the supplied design meets the voltage drop and power loss requirements. |

Precious Metal Mines in North America

| Installation Type | Mining Facility main medium voltage feeds, medium voltage and low voltage distribution load feeders. |

| Clients | Fluor (Vancouver, BC), AMEC (Vancouver, BC), Hatch Engineering (Vancouver, BC) & Meg-A-Ron Engineering (Winnipeg, MB) |

| Size | Multiple Projects, totaling over $1 million |

| System Rating(s) | 35kV, 15kV, 8kV, 5kV and 600V Service Feeders, 1200A – 4000A |

| Description | Cable bus has become a preferred option for several engineering groups in the US and Canada, and Advanced Cable Bus, Inc. has been selected to supply cable bus for several large and medium mining projects. In Latin America, the cable bus systems were specified with the goal of having reliable electrical feeders with materials that are suitable for the tropical climate. Cable bus was used for the mining processing plant’s main 35kV feeders, and distribution feeders at 15kV, 8kV, 5kV, and 600V including motor control feeders. Other served loads include milling and crushing motor loads, and lighting/heating loads. |

Precious Metal Mines in Latin America

| Installation Type | Mining Facility main medium voltage feeds, medium voltage and low voltage distribution load feeders |

| Clients | Fluor (Vancouver, BC) & Hatch Engineering (Mississauga, ON) |

| Size | Multiple Large Projects, totaling over $ 1.5 million |

| System Rating(s) | 35kV, 15kV, 8kV, 5kV and 600V Service Feeders, 1200A – 4000A |

| Description | Cable bus has become a preferred option for several engineering groups in the US and Canada, and Advanced Cable Bus, Inc. has been selected to supply cable bus for several large and medium mining projects. In Latin America, the cable bus systems were specified with the goal of having reliable electrical feeders with materials that are suitable for the tropical climate. Cable bus was used for the mining processing plant’s main 35kV feeders, and distribution feeders at 15kV, 8kV, 5kV, and 600V including motor control feeders. |

Community & Industry Involvement

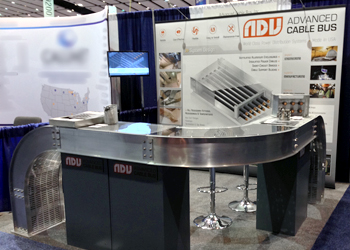

IEEE Power & Energy Society

Transmission & Distribution Conference & Exposition

The IEEE PES T&D conference is one of the largest electric power trade shows in the world. Organized by the IEEE Power and Energy Society (IEEE-PES) and held biannually, the conference boasts over 12,000 attendees.

Advanced Cable Bus, Inc. has been exhibiting at the IEEE PES T&D conference since 2010. At each event, we have established new and valuable relationships and strengthened existing ones. We would like to thank everyone who visited our booth in Chicago!

Clemson University Electric Power Research Association

Clemson, SC, USA

As a CUEPRA member, Advanced Cable Bus is proud to contribute to graduate student research activities on power systems. Research findings are distributed to member companies, published in academic journals, and presented to industry leaders at professional meetings and events. Also, the regular events and continuing work done by CUEPRA members and students provide opportunities, experiences and exposure for students who will become productive members of the electrical engineering community. We are proud to support the pursuit of knowledge and long-term energy solutions that CUEPRA represents.

Power-Gen International

/REWNA

Orlando, FL, USA

Advanced Cable Bus, Inc. exhibited for the first time at the Power-Gen International / Renewable Energy World North America (REWNA) / Nuclear Power International conference December 9-11, 2014 at Orange County Convention Center in Orlando, Florida.

We would like to thank everyone who took the time to stop by our booth; it is always a pleasure to interact with our colleagues in the power industry.

Greenville Chamber of Commerce

Greenville, SC, USA

As as an investor in the Greenville Chamber of Commerce, Advanced Cable Bus is committed to improving our local economy. All of our engineering and manufacturing is performed locally by South Carolina residents and American citizens.